The Same Box, But a Different Price. Practical Tips

Clients are often surprised to learn that boxes of the same style and with the same internal dimensions can have significantly different prices. The FEFCO 0201 shipping box is a classic example where prices can vary, even though the boxes may seem identical at first glance. Below, we explain two main reasons why this happens and what factors influence the price differences.

Note: Prices should only be compared when calculating the same production quantity of boxes. Comparing different order quantities is not accurate, as packaging prices always depend on the volume ordered.

1. Type of Corrugated Board

One of the main reasons for price differences is the type of corrugated board used for the box:

- Single-wall corrugated board consists of one fluted paper layer bonded between two flat linerboard layers. This type of board is lightweight and economical, making it the most popular material for FEFCO 0201 and other box styles.

- Double-wall corrugated board contains two fluted paper layers, which provide greater strength and durability. However, double-wall board is heavier and more expensive than single-wall board. It is typically used for packing heavier and more valuable goods.

A box that appears identical on the outside may be made from corrugated board with a different number of layers, resulting in significant differences in both price and strength.

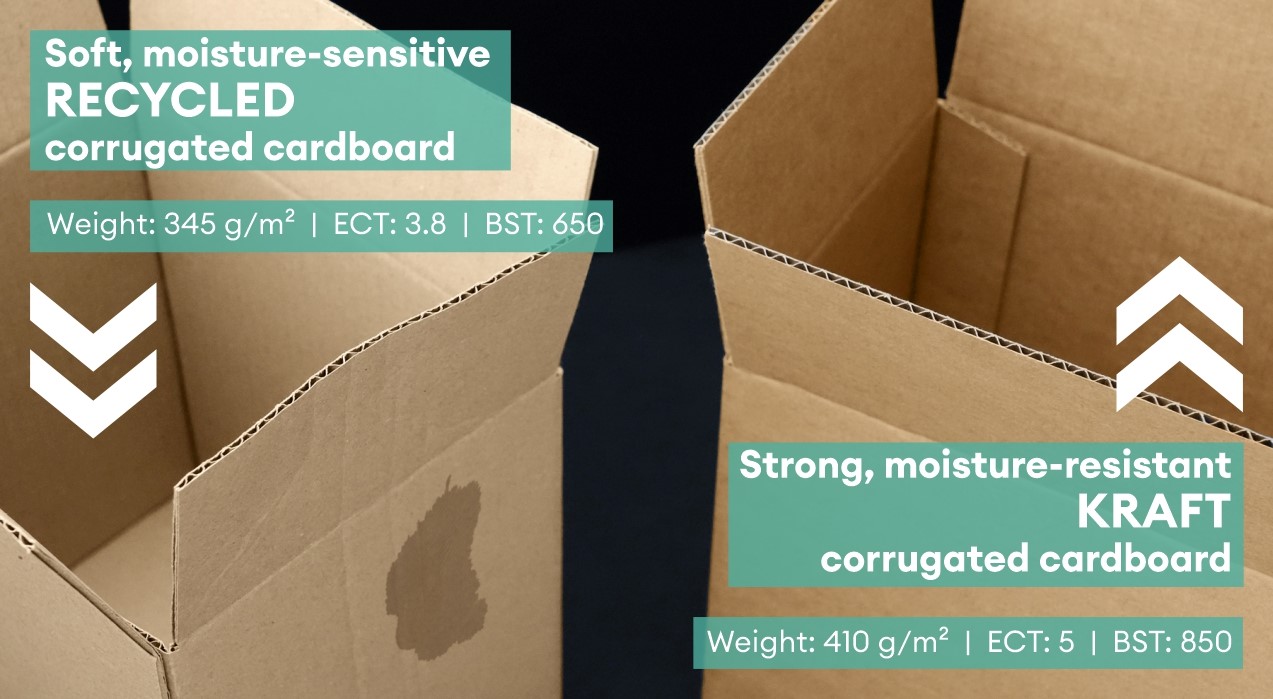

2. Physical Properties of Corrugated Board

Even if the corrugated board has the same structure (e.g., single-wall), it can differ significantly in its physical properties:

- Weight (gsm): The weight of the board layers affects the overall weight of the box and, consequently, the price.

- ECT (Edge Crush Test): This term is used to measure the board's vertical resistance to crushing and indicates the amount of weight that stacked boxes can withstand.

- BST (Burst Strength Test): BST measures the pressure the corrugated board can withstand before bursting. A higher BST value means better resistance to external pressure and impacts.

These differences in material quality can have a significant impact on the final price of the shipping box. Therefore, it is important to compare not only the price but also the physical characteristics of the corrugated board.

How to Ensure the Best Value for Your Money

To make informed and practical decisions and ensure the best balance between price and quality, consider the following tips:

- Clearly define your requirements: By understanding the type of corrugated board you need, you can avoid unnecessary expenses and ensure that the boxes' strength and quality meet your expectations.

- Specify the intended use of the packaging: Providing details about how and where the shipping boxes will be used helps your packaging supplier recommend the most suitable materials and offer the best price.

- Request samples of boxes made from different materials: Physically comparing different types of corrugated board can help you better understand the differences in quality and strength, allowing you to choose the right material for your needs.

By understanding the factors that influence the price of corrugated boxes, you can make better decisions and optimize your packaging budget while maintaining the necessary box quality.